Lorem ipsum dolor sit amet, dolor ponderum persequeris cum ex, no quo sale populo laboramus, pro homero mediocrem adipiscing no. Et harum fabellas pericula sed. Mei an alterum recusabo eloquentiam. Et enim choro pro. In justo ullum facer mel, delenit suavitate ut pro, sit verterem referrentur liberavisse at. No velit quidam aperiam quo, assum malorum cu ius.

For 15 years, Ranheat has manufactured ceramic filters for industrial biomass boilers. Proven longevity, ultra-low emissions, and retrofit-ready upgrades ensure long-term compliance and sustainability.

20 October 2025 | Alexander Franklin

For 15 years, Ranheat has manufactured ceramic filters for industrial biomass boilers. Proven longevity, ultra-low emissions, and retrofit-ready upgrades ensure long-term compliance and sustainability.

2 September 2025 | Alexander Franklin

Ranheat’s modular, repair-first biomass boilers can be re-tubed, rebuilt, and upgraded—keeping them in service for decades while reducing lifetime costs.

15 August 2025 | Alexander Franklin

Ranheat biomass boilers are built with one philosophy: fire always wins—so we design for it. Discover how our modular systems offer decades of reliability, rebuildability, and low lifetime cost.

14 August 2025 | Alexander Franklin

ORC systems have always worked—but today’s energy prices, modern manufacturing, and carbon goals make them an unbeatable upgrade. Discover why Ranheat biomass boilers are the ideal platform for generating electricity from wood waste heat.

24 July 2025 | Alexander Franklin

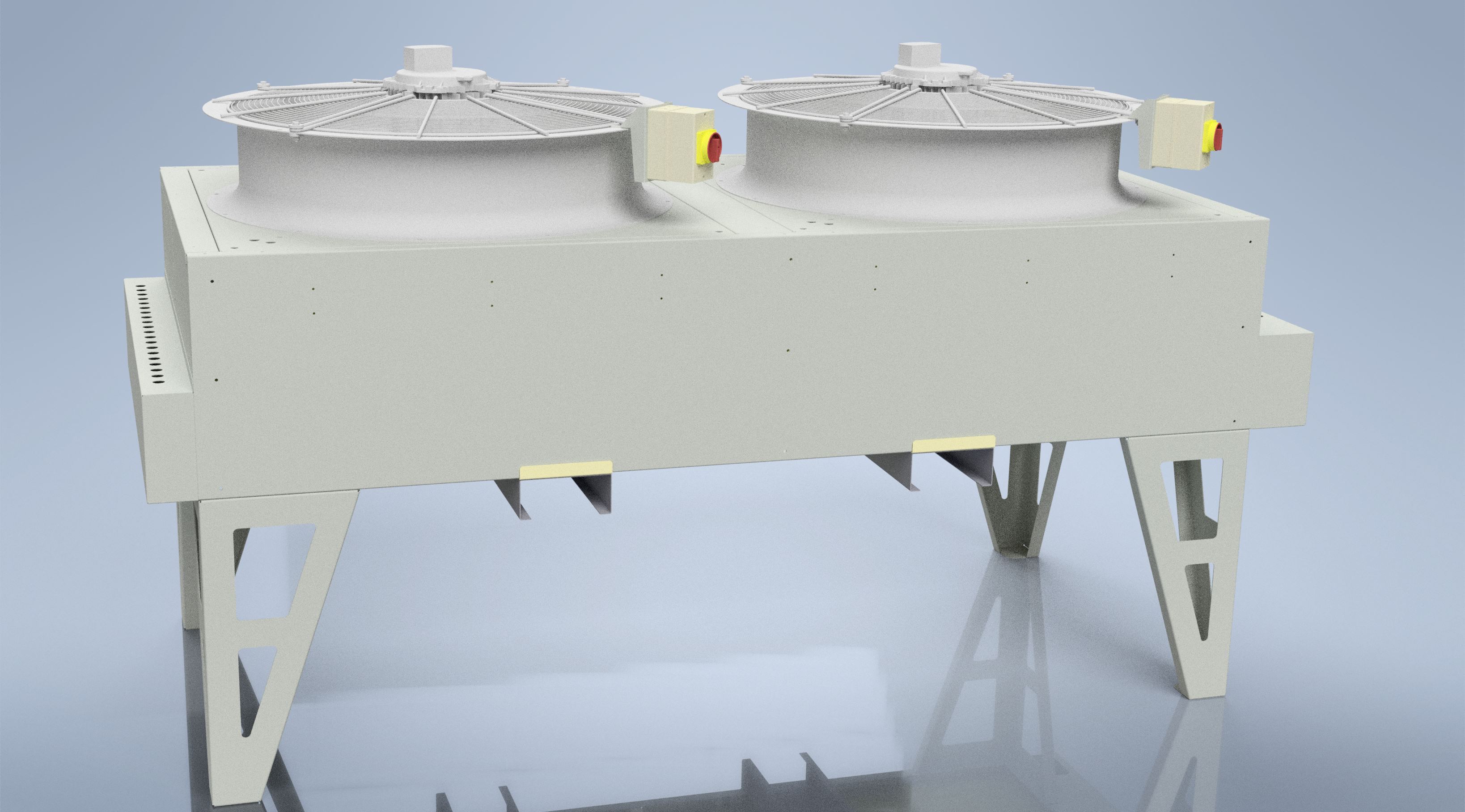

Ranheat biomass boilers are built to industrial standards—from fuel handling to fire chamber design. This article explains why our systems outperform commercial alternatives, especially for wood waste disposal, ORC integration, and long-term durability.

25 June 2025 | Alexander Franklin

Systems above 110°C trigger costly regulation. Learn how Ranheat biomass boilers and Enogia ORCs deliver efficient energy and heat—without crossing the PED line.

25 June 2025 | Alexander Franklin

Thinking about adding electricity generation to your biomass system? We explore when ORCs are a smart move for woodworking factories—and when they’re not.

12 June 2025 | Alexander Franklin

Ranheat’s biomass boilers—engineered for steady hot water output—work seamlessly with Enogia’s ORC systems to turn waste heat into renewable electricity. Ideal for woodworking factories needing waste disposal and power generation.

10 June 2025 | Alexander Franklin

Ranheat Engineering Ltd has a long-standing history as a family-run UK biomass boiler manufacturer. Learn how our modular designs, long-term support, and partnership with Danstoker deliver industrial heating solutions built to last.

4 June 2025 | Alexander Franklin

Ranheat Engineering Ltd has a long-standing history as a family-run UK biomass boiler manufacturer. Learn how our modular designs, long-term support, and partnership with Danstoker deliver industrial heating solutions built to last.

3 June 2025 | Alexander Franklin

Not all 300kW biomass systems are equal. Ranheat systems are built like lorry diesel engines: heavy-duty, serviceable, and made to last. Discover what that means for your factory or plant.

29 May 2025 | Alexander Franklin

Ranheat industrial biomass boilers are engineered for endurance. Discover why our radiant-first design, modular layout, and real-world fuel tolerance give you better value over the long term.

16 May 2025 | Alexander Franklin

Hot water from biomass boilers is one of the most flexible heating sources in woodworking factories. Learn how to use it for offices, kilns, spray lines, and more—using your own wood waste.

6 May 2025 | Alexander Franklin

Learn how to calculate heating requirements for a woodworking factory. From conduction losses to ventilation and process heating, Ranheat breaks down what you need to size an industrial biomass boiler.

30 April 2025 | Alexander Franklin