Convert waste into energy.

Turn offcuts, shavings and MDF fines into reliable heat. Ranheat systems close the loop by turning everyday waste into an on-site energy source.

Redefine your energy source.

Use the wood waste your process already produces — or low-cost local biomass — to reduce fossil fuel consumption and stabilise heating costs.

Built in the UK.

Designed, fabricated and assembled in Northampton. Industrial-grade components and repairable engineering ensure long service life and dependable support.

Lower lifetime running costs.

Fuel flexibility, accessible components and smart controls reduce downtime, simplify maintenance and deliver predictable long-term operating costs.

What we do.

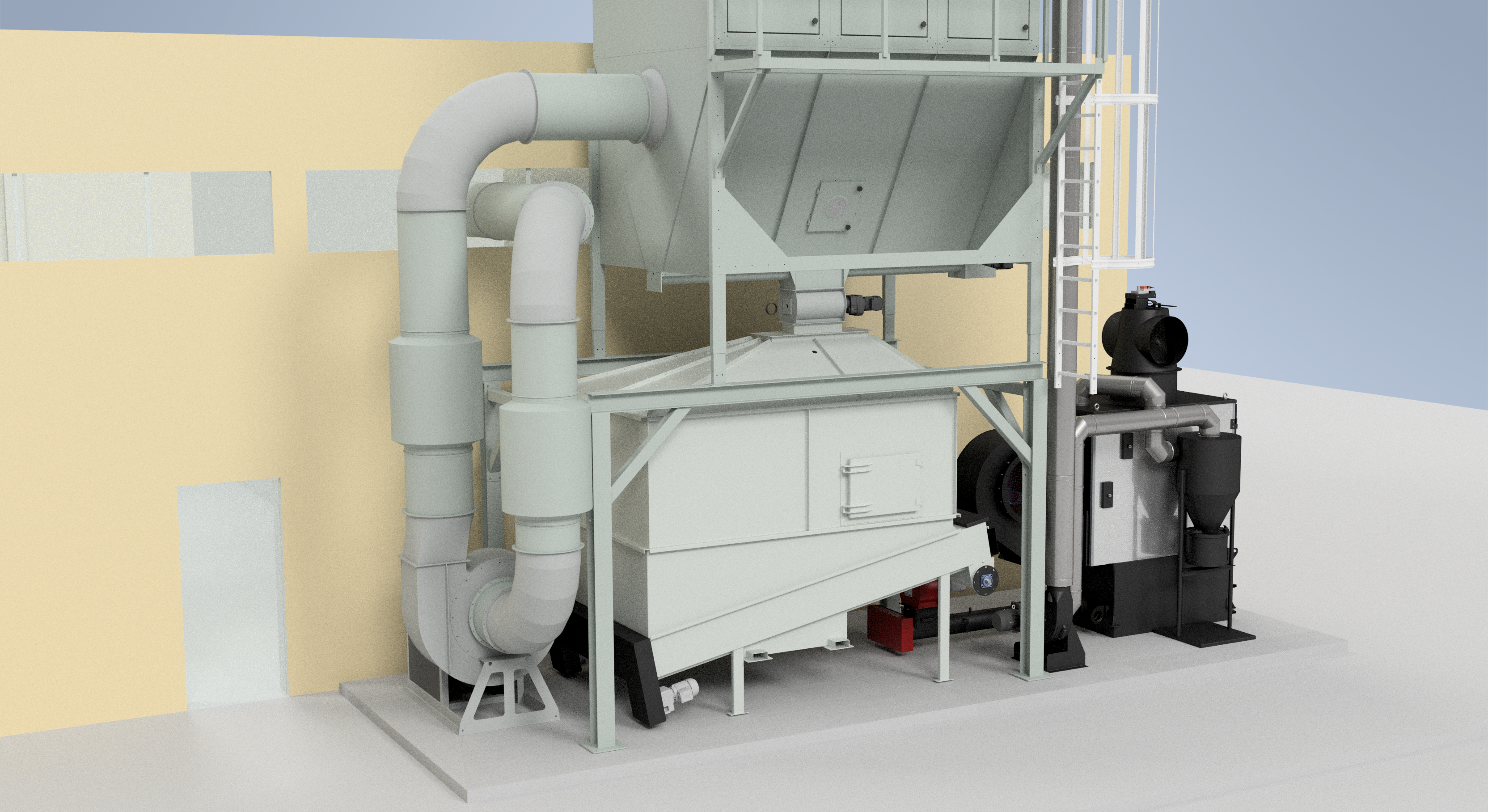

We turn unavoidable wood waste into a controlled energy source through industrial combustion engineering, intelligent PLC-based controls and site-specific system design. Every system is configured around the real conditions of your factory — variable fuel types, changing production volumes, space constraints and the need for consistent, reliable heat.

Our approach covers the full lifecycle. We assess your waste stream, match the right boiler or warm-air solution, integrate silos and fuel handling, and provide long-term support through servicing, parts and remote diagnostics. The result is predictable performance, stable running costs and equipment designed to operate for decades.

We build combustion systems engineered specifically for MDF, chipboard, mixed fines and real production waste — not pellet-only domestic units.

Robust construction, serviceable components and PLC-based controls provide stable operation, clear diagnostics and long-term reliability in industrial environments.

We assess your waste stream, heat demand, space constraints and processes to configure a system that integrates cleanly with your factory layout.

From servicing and parts to remote monitoring and diagnostics, Ranheat systems are supported for long operational life and predictable running costs.

How it works

Wood waste from your production line is gathered, processed and delivered directly to the boiler. The system handles the feed automatically, keeping things clean and consistent.

Inside the boiler, this fuel is burned to produce heat for your workspace or heating system. The result is a practical, efficient way to make better use of material you already generate.

Our Systems

Biomass heating systems designed around your waste and your site.

Our product range covers everything from fuel storage and handling to combustion, heat exchange and heat distribution. Every component is built for industrial environments and engineered to work with MDF, chipboard, softwood, hardwood and mixed fines.

We combine robust engineering with practical configuration to ensure your system delivers stable heat output and fits cleanly into your existing processes. Each solution is designed for reliability, serviceability and long-term performance in real production settings.

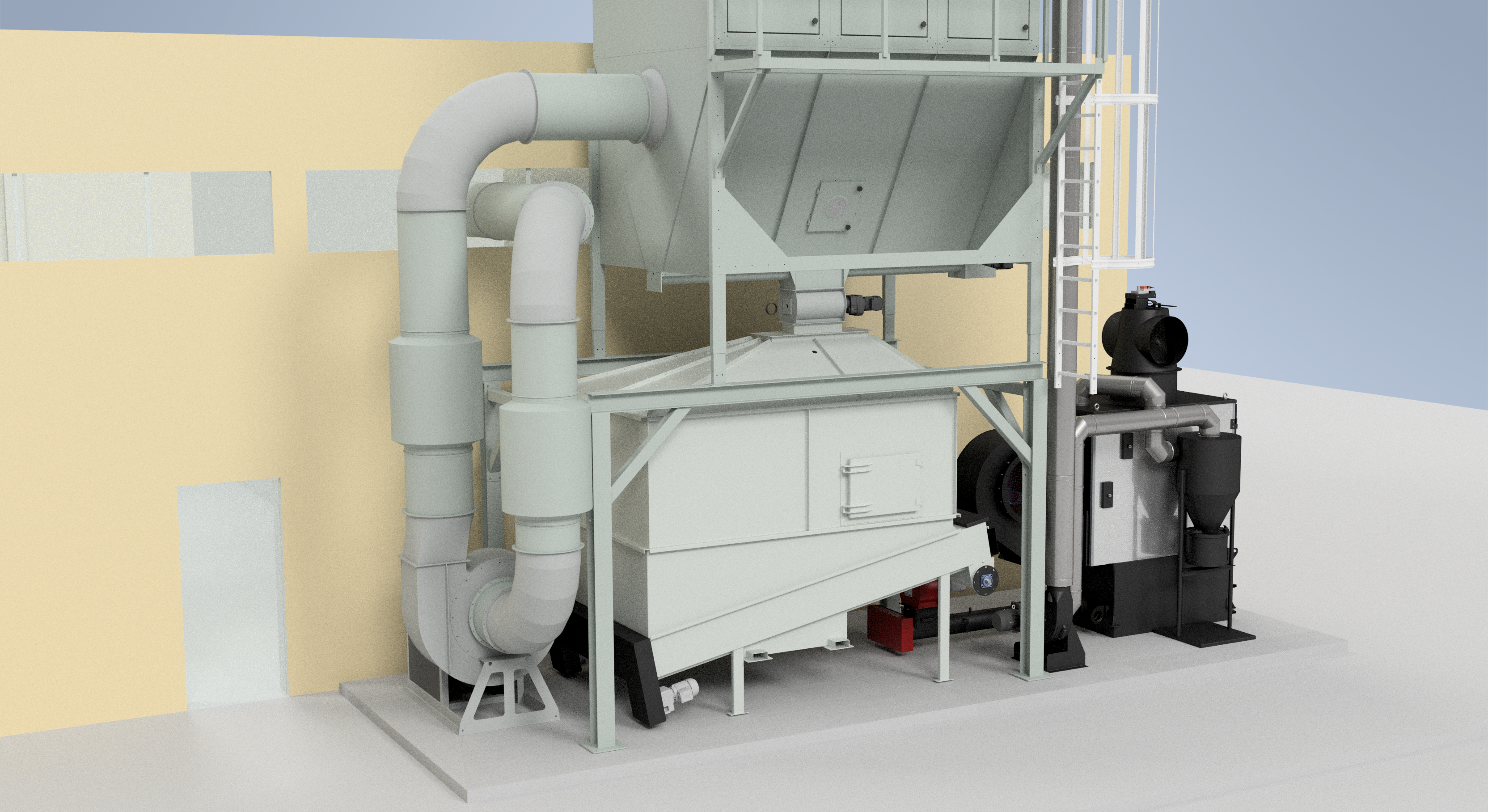

WA150

Subtitle Description

Graeco blandit honestatis ad eos, mea fuisset euripidis te. Mei id accumsan antiopam corrumpit, nobis affert conceptam no eam. Vim te aperiri instructior, an mutat essent iudicabit eos, vis cu sumo labore bonorum.

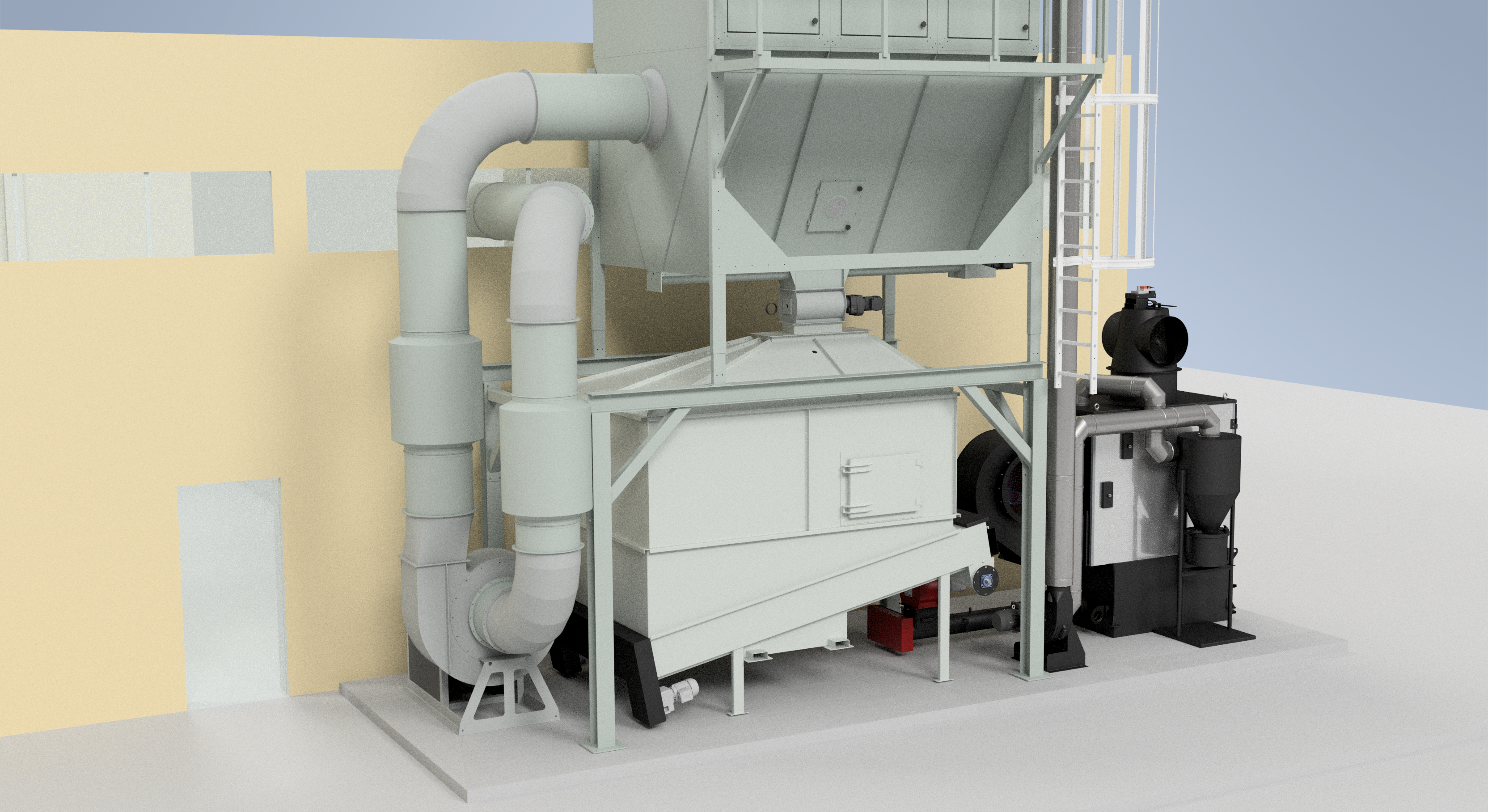

WA150

Subtitle Description

Graeco blandit honestatis ad eos, mea fuisset euripidis te. Mei id accumsan antiopam corrumpit, nobis affert conceptam no eam. Vim te aperiri instructior, an mutat essent iudicabit eos, vis cu sumo labore bonorum.

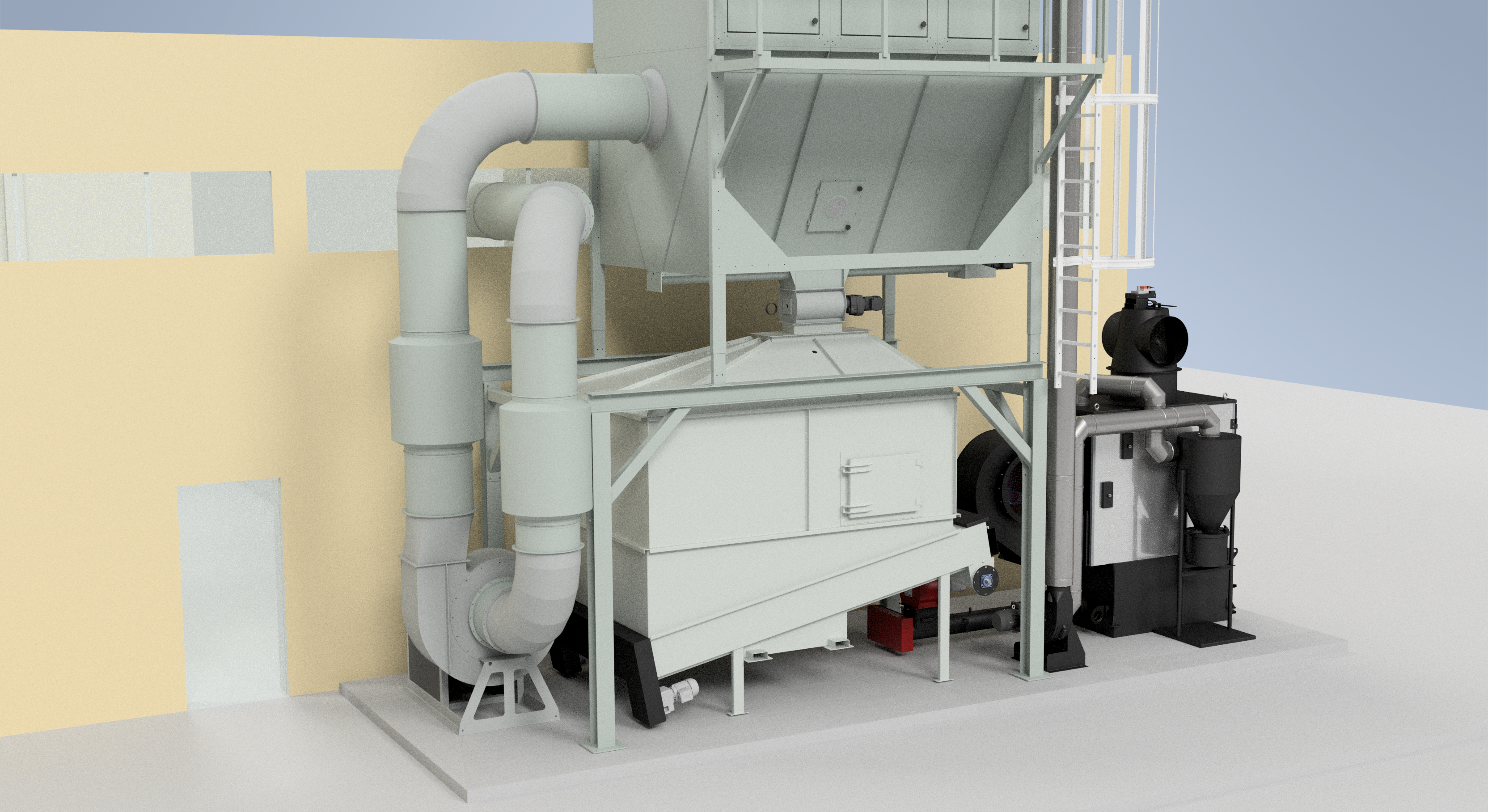

WA150

Subtitle Description

Graeco blandit honestatis ad eos, mea fuisset euripidis te. Mei id accumsan antiopam corrumpit, nobis affert conceptam no eam. Vim te aperiri instructior, an mutat essent iudicabit eos, vis cu sumo labore bonorum.

WA150

Subtitle Description

Graeco blandit honestatis ad eos, mea fuisset euripidis te. Mei id accumsan antiopam corrumpit, nobis affert conceptam no eam. Vim te aperiri instructior, an mutat essent iudicabit eos, vis cu sumo labore bonorum.

Case Studies

Ranheat systems operate on over 700 sites, from small joinery workshops to large manufacturing facilities. Each installation shows how our equipment handles mixed wood waste and delivers reliable heat under real production conditions.

These case studies offer practical insight into system design, day-to-day operation and long-term performance. They demonstrate how businesses use their unavoidable waste stream as a dependable energy source.

Corporate responsibility

We maintain relevant memberships to align our work with recognised industry standards and expectations.